-

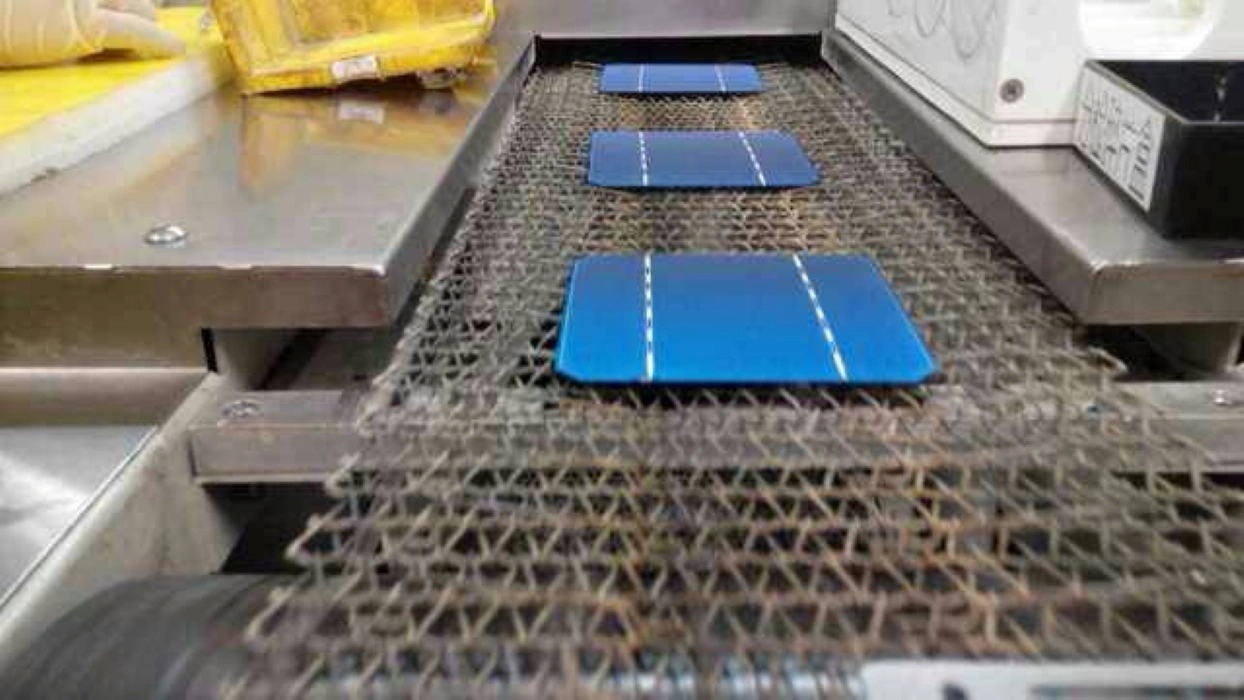

Solar Production Line – Key Technology for Stable Conveying|Single-Track Belt Application Case

In this project, a single-track solar conveyor belt was implemented, specifically designed for the stable transport of solar cells along the production line. With excellent heat resistance and surface flatness, it enables precise handling of thin solar wafers during cleaning, coating, and heat treatment processes. This solution provides a reliable and indispensable conveying system for manufacturing in the photovoltaic industry.

-

Solar Production Line – Key Technology for Stable Conveying|Single-Track Belt Application Case

In this project, a single-track solar conveyor belt was implemented, specifically designed for the stable transport of solar cells along the production line. With excellent heat resistance and surface flatness, it enables precise handling of thin solar wafers during cleaning, coating, and heat treatment processes. This solution provides a reliable and indispensable conveying system for manufacturing in the photovoltaic industry.

-

Practical Application Case|Chain-Driven Mesh Belt in Food Processing Lines

In high-cleanliness, high-efficiency food processing lines, the chain-driven conveyor belt ensures stable transport of large food products while supporting high-speed cutting and large-scale packaging, significantly improving production efficiency. With high strength and excellent resistance to oil and heat, it is well-suited for food processing operations that require long-term stable performance.

-

Practical Application Case|Chain-Driven Mesh Belt in Food Processing Lines

In high-cleanliness, high-efficiency food processing lines, the chain-driven conveyor belt ensures stable transport of large food products while supporting high-speed cutting and large-scale packaging, significantly improving production efficiency. With high strength and excellent resistance to oil and heat, it is well-suited for food processing operations that require long-term stable performance.

-

Powder Metallurgy Heat Treatment|Balanced Weave Conveyor Belt Application Case

In this case, a balanced weave conveyor belt was used in the powder metallurgy process to transport large volumes of metal parts into a high-temperature furnace for sintering. The belt provides high strength and stable conveying performance, capable of withstanding extreme heat while maintaining precise alignment of workpieces. This ensures improved heat treatment efficiency and consistent product quality.

-

Annealing Furnace Application|Balanced Weave Conveyor Belt Case

In this case, an annealing furnace was equipped with a balanced weave conveyor belt, offering an excellent strength-to-weight ratio and outstanding heat resistance. The belt ensures stable conveying of workpieces during continuous annealing, maintaining precise alignment without side wandering or deformation under high-temperature conditions. It is particularly suitable for metal heat treatment lines and high-temperature processes, effectively enhancing production efficiency and product consistency.

-

High-Temperature Forging|Heavy-Duty Performance with Chain-Driven Mesh Belt

In this case, a chain-driven metal mesh belt was implemented, specifically designed for conveying forged workpieces through high-temperature furnaces. With exceptional load-bearing capacity and heat resistance, it is well-suited for pre-forging heating and heat treatment applications. The chain drive, combined with a reinforced structure, ensures stable operation of large metal billets inside the furnace, making it a key solution for reliable conveying in heavy industrial production lines.

-

Application of Compound Balanced Weave Conveyor Belt in Heat Treatment Equipment

In this case, a compound balanced weave conveyor belt was used in conjunction with a high-temperature furnace, specifically designed for a screw heat treatment plant to perform surface treatment and hardening operations. The belt features high load capacity, excellent heat resistance, and stable temperature distribution, ensuring consistent quality of workpieces during continuous conveying. It is an ideal choice for hand tool and hardware heat treatment processes.