Professional Processes × Customized Flexibility × International Quality

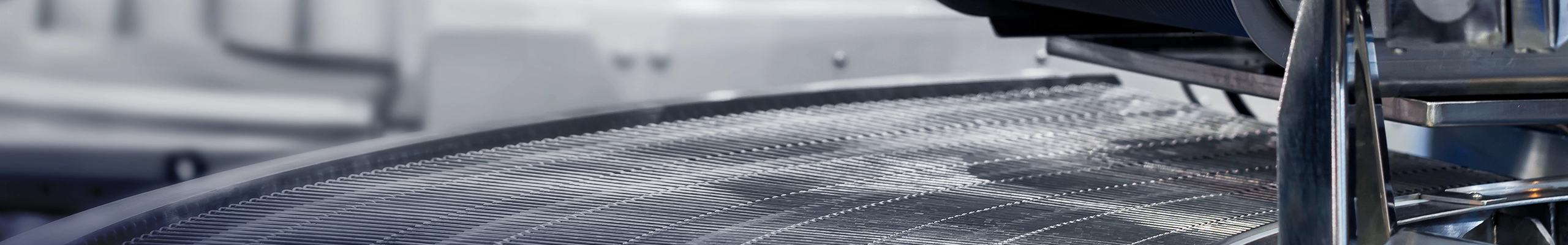

In the rapidly evolving field of industrial manufacturing, we understand that "stable quality" and "application adaptability" are the core values of metal conveyor solutions. For years, we have not only focused on product manufacturing but also dedicated ourselves to technical advancements and process optimization to provide reliable engineering support and efficient application results for various industries.

01. Highly Stable Process

01. Highly Stable Process

We use professional precision equipment and standardized management processes, along with an experienced production team. This ensures that every batch of our metal mesh belts, conveyor belts, and other products achieves consistent quality in dimensional accuracy, structural strength, and durability. Our products can reliably withstand harsh conditions such as long-term operation, high temperatures, and high tension.

02. Flexible Customization Support

02. Flexible Customization Support

We provide material selection recommendations and structural design assistance based on a client's equipment needs, production line processes, application temperatures, and environmental conditions. We can assist with everything from sample prototyping and verification to mass production implementation. This helps clients optimize product compatibility and operational efficiency.

03. Carefully Selected Materials and International Standards

03. Carefully Selected Materials and International Standards

Our products use certified wire materials from companies like Japan's Nippon Seisen Co., Ltd., which offer high heat resistance, corrosion resistance, and stable strength. We also use different grades of stainless steel, such as SUS304, SUS310, and SUS314, depending on the application, to balance durability with cost-effectiveness. Our products comply with equipment standards and food-grade regulations in multiple countries.

04. Engineering Collaboration Mindset

04. Engineering Collaboration Mindset

We don't just provide a single product; we prioritize the overall matching and application efficiency of the entire conveyor system. Whether for traditional conveyor structures, special engineering equipment, or fully automated production lines, we can collaborate with engineering teams from the design stage. We consider the convenience of installation, maintenance, and future part replacement in advance to reduce downtime risks and overall maintenance costs.

05. Long-Term Technical Tracking and Quality Management

05. Long-Term Technical Tracking and Quality Management

We maintain production records and delivery management mechanisms for every product to ensure on-time delivery and traceability. We also regularly follow up with clients on their application status and provide ongoing optimization suggestions for equipment adjustments and new applications. This allows each collaboration to become a source of technical upgrades.